Revolutionizing Procurement Through Autonomous Sourcing

Sponsored Content

By Magnus Bergfors, Keelvar

After a couple of years of supplier collaboration, sustainability and risk management dominating the agenda, cost savings is climbing the charts again. In times of inflation and economic uncertainty, organizations are turning to procurement to help drive savings and efficiencies.

Alas, this has not translated into more resources: Workforce shortages, restricted capacity and increased demand are causing considerable strain on the procurement profession. While automation alone cannot solve these concerns, it can revolutionize how buyers and suppliers handle sourcing events and enable them to make better, faster decisions in the face of unpredictability.

As real-time demands grow, we've witnessed an increase in off-contract spot bidding to take advantage of volatile markets. Teams at some Keelvar customers are now responsible for executing hundreds of these types of operational, ad hoc bidding events each year. Unfortunately, companies don't always have time to bid competitively on all of these lanes or take all of the best practice procedures.

Part of the solution to this problem is automation. By leveraging state-of-the art technology, companies can automate many of the time-consuming operations connected with the spot bidding process, like starting events, inviting and tracking bidders, evaluating bid data, advising optimal award decisions, managing pricing adjustments, and auditing. This makes it easy to establish competition, even in low-budget events, and assures that the best offer is discovered and granted in a timely manner every time. It also guarantees that all of this data is saved and tracked centrally, rather than in people's inboxes or, worse, in their minds.

Employees can focus on strategic decision-making with this level of automation. Our clients have experienced up to 93-percent time and productivity savings. Automatic sourcing enables employees to go to market whenever they need it, 24 hours a day, seven days a week, to source as needed, which is a major advantage in today's highly competitive markets.

This also frees up time for sourcing professionals who no longer have to deal with urgent requests that often disrupt other more strategic initiatives. And the need for digitization is undeniably increasing. The need to be agile and respond quickly to severe supply chain interruptions or other events has never been greater, and automation enables this.

Nonetheless, some firms are still unwilling to completely embrace digitization. Some rely on antiquated systems that need inordinate amounts of time and manual labor to fulfill tasks. These time-consuming activities render companies prone to errors and can severely jeopardize their supply networks.

The most successful businesses understand that no combination is more powerful than workers and the proper technology. Automation performs operations that would ordinarily take people hours (or even days) to do. As a consequence, operational efficiency improves, expenses fall, and the workforce has more time to focus on strategic initiatives that fuel future development and establish critical connections — abilities that technology cannot replace.

What is the next stage in sourcing automation?

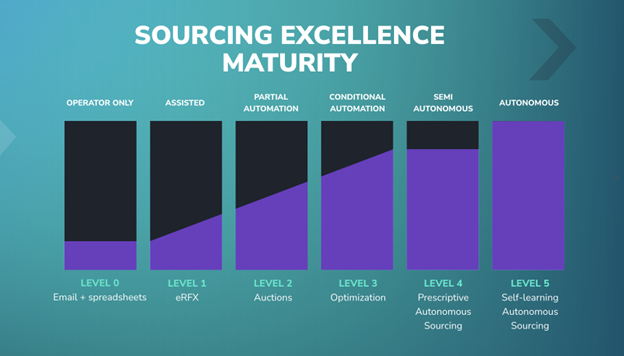

At the moment, the most sophisticated automation technology is at Level 4 — prescriptive autonomous sourcing on the scale below. This level comprises sourcing bots that can execute jobs previously handled by people. For certain of those jobs, a human must still accept a choice for the bot before it can proceed with further actions. Overall, the bots have a high level of autonomy but are not entirely self-driving.

Sourcing Excellence Maturity scale - Copyright Keelvar

Future leaders are aggressively developing and exploiting data science to progress intelligent bots to Level 5, which means they are entirely autonomous and can even begin themselves, depending on external market triggers or internal data signals. When this day arrives, people will be able to devote more time to strategic thinking about their supply chains, risk profiles and carrier partnerships. The key to this freedom is automation.

Magnus Bergfors is director of product marketing at Keelvar.