Strategic Sourcing Lessons from My Health-Care Journey

“We can’t provide an estimated cost.”

“We will bill you after the visit.”

“We don’t guarantee outcomes.”

“Please arrive 15 minutes early, but expect to wait past your scheduled time.”

As sourcing professionals, we’d never tolerate such uncertainty in our supplier relationships. We demand clear pricing, defined service levels and guaranteed delivery dates. Our stakeholders would be appalled if we signed contracts without knowing costs or accepting undefined performance metrics.

Yet every day, as patients in the U.S. health-care system, we do exactly that. We accept what, according to numerous reports, is the world’s highest health-care pricing, uncertain delivery and questionable service levels that would get any supplier immediately disqualified from approved vendor lists.

As a veteran supply chain executive, I recently found myself navigating these exact challenges when sourcing my own health-care services. And the experience revealed striking parallels to the pitfalls many organizations face in their strategic sourcing initiatives.

When Personal Meets Professional

U.S. health-care costs have been high for years. Faced with an upcoming need for physical therapy, I decided to apply the same strategic sourcing principles I’ve used for decades in business. The results were both enlightening and concerning, offering valuable lessons for organizations undertaking strategic sourcing initiatives in any industry.

Step 1: Spend analysis. Just as with any major category, I began by analyzing my 2024 medical expenses and forecasting 2025 requirements. This initial step revealed physical therapy as a significant spend category — a "low-hanging fruit" for optimization, or so I thought.

Step 2: Assess the supply market. The market appeared promising. Multiple providers were within my insurance network; all were accepting new patients, suggesting healthy competition. However, as many procurement professionals know, surface-level market analysis doesn’t always tell the complete story.

Step 3: Develop the sourcing strategy. Based on past experience and spend analysis, I categorized physical therapy as a critical service requiring a value-focused approach. This classification would later prove to be one of the several strategic missteps — a common error in organizational sourcing initiatives.

Step 4: Prepare the statement of work (SOW). Armed with my doctor’s recommendations, I developed what I believed to be a clear scope of work. Yet, like many requirements documents in business, the reality proved more complex than anticipated.

Step 5: Identify sources. I worked with two offices in the past; both provided quality services and are within 2 miles of my house. So the supplier selection decision came down to price.

Step 6: RFQ. Here’s where theory met reality. What should have been a straightforward quote comparison between two local providers turned into a labyrinth of procedure codes, insurance protocols and reluctant stakeholders. Does this sound familiar to anyone who’s tried sourcing from new markets or highly regulated industries?

After hours of persistence, multiple phone calls and countless transfers, I finally gathered enough information to make a comparison. The process revealed striking similarities to the challenges organizations face when attempting to source from industries with different business cultures or communication norms.

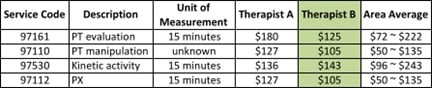

Step 7: Select the supplier. The quote evaluation and comparison weren’t perfect, but they gave me enough information to decide. (See chart.)

Common Pitfalls of Strategic Sourcing

This perceived straightforward sourcing task turned out to be a lot more involved than I had expected. It also had mixed results. What I thought would be a quick phone call to compare the two quotes took several hours of my time. After selecting a lower-cost provider, I still felt being ripped off when compared with the market.

After reflection, I realized I had stepped into a few pitfalls common to the strategic sourcing process:

Poor data integrity. Just as my inability to access standardized procedure codes hindered effective quotation, many organizations struggle with inconsistent SKU numbers across locations. In manufacturing, I’ve seen countless sourcing initiatives stall because part numbers varied between plants or specifications weren’t standardized.

Misaligned relationship expectation. My attempt to establish a critical relationship with what the provider saw as a transactional service mirrors a common business challenge. Not every supplier relationship needs to be strategic, and misalignment of expectations can waste resources on both sides.

Limited value creation mindset. By focusing solely on performance metrics (quality, service, price), I slipped into the traditional procurement mindset of maximizing value from a supplier. Had I been more cognitive with my objective of improving my well-being, rather than choosing the best source, I could have identified other opportunities, like telehealth options or preventive care programs. This parallels how organizations often limit themselves to traditional supplier relationships instead of exploring collaborative value-creation opportunities.

Limited access to qualified supply base. Limiting myself to incumbent suppliers mirrors how many organizations constrain themselves to a less-diversified supply base or blindly following the trend of nearshoring, potentially missing innovative or cost-effective alternatives. Digital solutions and global sourcing often open new possibilities, like Zoom care. In my case, I planned to travel internationally, so I could access local providers who performed at a similar quality level for a fraction of the cost.

System complexity underestimation. The U.S. health-care system’s complexity reflects challenges many organizations face when sourcing from highly regulated industries or entering new markets. Understanding the ecosystem’s dynamics is crucial for effective sourcing.

Recommendations for Modern Strategic Sourcing

The pitfalls I encountered personally are quite common with organizations that are new to strategic sourcing or are re-embracing strategic sourcing in today’s volatile world. In the last few years, many companies have reacted to trade policy changes and geopolitical shifts without thinking through the strategic sourcing process. They often got trapped in these common pitfalls.

Well-executed strategic sourcing enables supply chain professionals to maximize the value for their businesses. These four best practices can help organization avoid strategic sourcing’s common pitfalls:

1) By embracing digital tools, modern procurement platforms can automate spend analysis, expand supplier access, and streamline sourcing and bidding processes. These tools are particularly valuable for indirect categories, in which market transparency is limited.

2) Leverage artificial intelligence (AI) for data management. While the strategic sourcing process starts with spend analysis, many organizations realize a large gap exists between poor data management and data integrity. Master data is not being maintained appropriately, inconsistent across locations, or just simply wrong.

AI can significantly improve master data quality and spend analysis accuracy. Organizations can reduce data cleansing time by 60 percent while improving classification accuracy through AI implementation.

3) By implementing digital supply chain mapping, organizations can understand where the sub-tier suppliers are located and where sub-components are produced, both crucial for risk management and strategic decision-making. Digital mapping tools provide visibility into sub-tier suppliers, potential vulnerabilities and exposure to tariff costs.

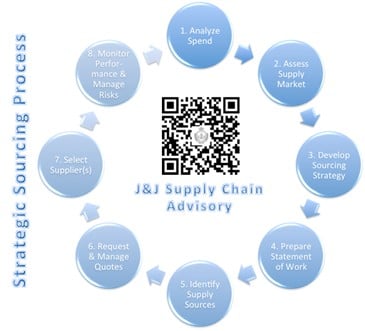

4) Develop comprehensive sourcing plans. While technology enables better execution, success still requires thorough planning. In a strategic sourcing process (see graphic), organizations should clearly define category objectives and constraints, assess stakeholder requirements and influence, map system complexities and relationships and plan for change management and adoption.

Looking Ahead

As supply chain uncertainties and inflation pressures continue, the principles of strategic sourcing remain crucial for supply management organizations. However, successful execution requires adapting these principles to modern challenges while leveraging new technologies and approaches.

My health-care sourcing experience serves as a reminder that even familiar processes can yield new insights when viewed through a different lens.

As supply chain professionals, we must continue to learn, adapt and improve our approaches to strategic sourcing, regardless of the category or industry.